English

Views: 0 Author: Site Editor Publish Time: 2024-05-16 Origin: Site

A. Defining CNC Machining: A Versatile Manufacturing Process

CNC machining, an acronym for Computer Numerically Controlled machining, encompasses a wide range of subtractive manufacturing processes guided by computer instructions. These processes involve meticulously removing material from a workpiece, typically a block of metal, plastic, or wood, to transform it into a desired shape or form.

CNC machining offers a plethora of advantages, including:

Unparalleled Precision: CNC machines operate with extreme accuracy, ensuring that dimensions, tolerances, and surface finishes meet even the most stringent requirements.

Enhanced Efficiency: CNC processes are highly automated, minimizing human error and maximizing production rates.

Remarkable Versatility: CNC machining can handle a diverse range of materials and create intricate geometries, catering to a broad spectrum of applications.

B. Introducing CNC Milling: A Specialized Approach to Precision Machining

Within the domain of CNC machining, CNC milling stands out as a specialized technique that utilizes rotary cutting tools to sculpt material from a workpiece. The workpiece remains stationary while the cutting tool moves along multiple axes, enabling the creation of complex 2D and 3D shapes.

CNC milling excels in producing:

Intricate Features: CNC mills can generate intricate details, such as grooves, holes, and contoured surfaces, with remarkable precision.

Complex Geometries: CNC milling is adept at creating complex 3D shapes, making it ideal for applications that demand intricate designs.

High-Precision Components: CNC mills are instrumental in manufacturing high-precision components for various industries, including aerospace, automotive, and medical.

CNC machining encompasses a diverse array of techniques, each tailored to specific applications and material types. Some of the most common CNC machining processes include:

CNC Milling: As discussed earlier, CNC milling utilizes rotary cutting tools to remove material from a workpiece.

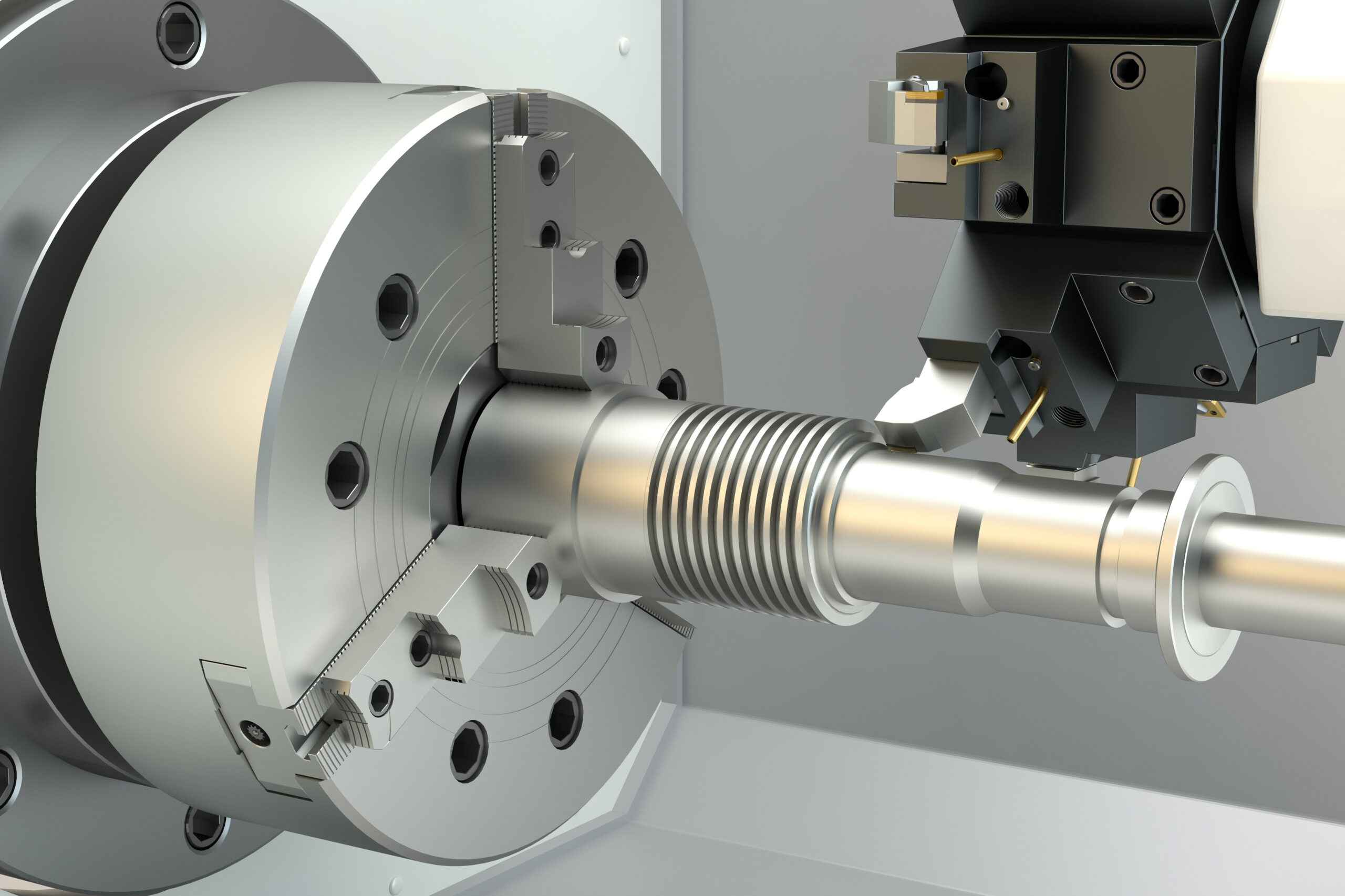

CNC Turning: In CNC turning, the workpiece rotates while the cutting tool remains stationary, enabling the creation of cylindrical and rotational shapes.

CNC Drilling: CNC drilling involves using drill bits to create precise holes in a workpiece.

CNC Grinding: CNC grinding employs abrasive wheels to achieve ultra-fine finishes and tight tolerances.

CNC milling operates on the principle of material removal by a rotating cutting tool. The workpiece is typically secured to the machine bed, while the cutting tool moves along three primary axes:

X-axis: Controls horizontal movement from left to right.

Y-axis: Controls vertical movement forward and backward.

Z-axis: Controls depth of cut, moving the tool up and down.

The combination of these movements allows the cutting tool to precisely navigate the workpiece, creating intricate features and complex geometries.