English

Views: 0 Author: Site Editor Publish Time: 2024-05-13 Origin: Site

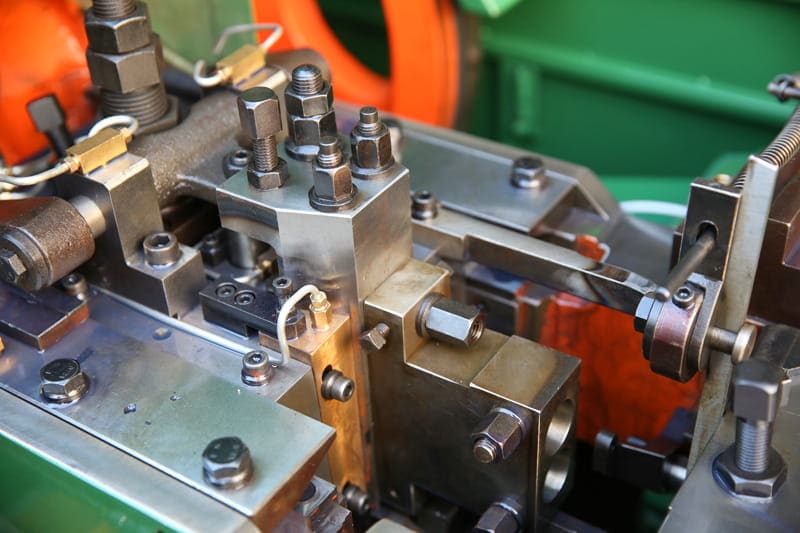

In manufacturing, cold heading is a key process for manufacturing high-quality precision parts. Cold heading involves the use of specialized machinery to form metal wire into various shapes and sizes. The process is widely used in the production of fasteners, bolts, screws and other components in industries such as automotive, aerospace and construction. To achieve the highest levels of precision and quality for cold-headed parts, companies often turn to custom cold-heading services.

Custom cold heading services play a vital role in meeting the specific needs of manufacturers who require unique and precise cold heading parts. These services provide customized solutions for producing parts that meet precise specifications, tolerances and performance requirements. By leveraging the expertise of a custom cold heading service provider, manufacturers can ensure the production of high-quality parts that meet the most stringent industry standards.

One of the main advantages of custom cold heading services is the ability to manufacture parts with complex geometries and complex designs. By using advanced cold heading machinery and specialized tooling, custom service providers can produce parts with precise shapes, threads and features. This capability is especially valuable for industries that require complex and custom-designed components, such as automotive and aerospace.

In addition, custom cold heading services enable manufacturers to optimize the material and production costs associated with cold heading parts. By working closely with a custom service provider, manufacturers can benefit from expert guidance on material selection, mold design and process optimization. This collaborative approach helps minimize waste, reduce production time, and ultimately reduce overall manufacturing costs.

In addition to precision and cost-effectiveness, custom cold heading services also offer the advantage of scalability. Whether manufacturers require low-volume or high-volume production, custom service providers can meet different production needs. This flexibility enables manufacturers to adapt to changing market demands and effectively manage their inventory levels.

When working with a custom cold heading service provider, manufacturers can also benefit from the expertise and experience of the service team. Custom service providers typically have in-depth knowledge of cold heading processes, metallurgy, and quality control standards. This knowledge enables them to provide valuable insights and advice throughout the production process, ensuring that the final part meets the highest quality and performance standards.

In addition, custom cold heading services can provide added value through secondary processing and finishing services. From heat treatment and surface coating to precision machining and assembly, custom service providers can provide comprehensive secondary processing to further enhance the functionality and appearance of cold-forged parts.

In summary, custom cold heading services play a key role in the production of precision cold heading parts. By leveraging the expertise, capabilities and flexibility of custom service providers, manufacturers can achieve superior quality, cost-effectiveness and scalability in the production of cold-forged parts. As the demand for custom-designed and high-performance parts continues to grow, custom cold heading services remain critical to meeting the changing needs of various industries.